When we ask Google about recommendation systems, it defines them too narrowly as “a subclass of information filtering system that attempts to predict the ‘rating’ or ‘preference’ that a user would assign to an item.” However, I believe, recommender systems are systems that assist users in discovering items that they may be interested in.

Recommender systems are among the most visible and successful practical applications of Artificial Intelligence and Machine Learning technology. Such systems now accompany us in our daily online lives, such as on e-commerce sites, media streaming platforms, and social networks. They assist us by suggesting items that are supposed to be of interest to us and thus likely to be inspected, consumed, or purchased. Recommendations are typically designed to serve a specific purpose and create a specific value for the consumer and the provider.

The business value of recommenders and their reports:

Recommender systems claim to reduce churn while increasing sales. However, you might be wondering how they measure their actual success. What is it that you should also consider? And what metrics should you take into account when you’re building your recommendation system?

Companies rarely share specifics about how they profit from the use of recommendation technology and how frequently their customers adopt recommendations. In a blog post, Netflix revealed that “75% of what people watch is from some sort of recommendation,” and YouTube reports that 60% of home screen clicks are on recommendations. As a result, they estimate the annual business value of recommendation and personalization to be more than USD 1 billion.

The way companies measure the effects and business value of a deployed recommender system is determined by a variety of factors, including the application domain and, more importantly, the company’s business model. In this case, the goal could be to increase the number of time users spend using the service. Increased engagement is also a common goal for businesses with a flat-rate subscription model, as engagement is often viewed as a proxy for retention. A recommender’s impact can be more direct in other domains.

The corresponding goals are to either directly promote sales via the recommender or to influence consumer behavior toward more profitable items. The underlying business models and objectives determine how companies measure the value of a recommender in all of the cases mentioned. In that context, relevant business metrics include sales or revenue, click-through rates (CTR), higher user engagement, and customer retention rates.

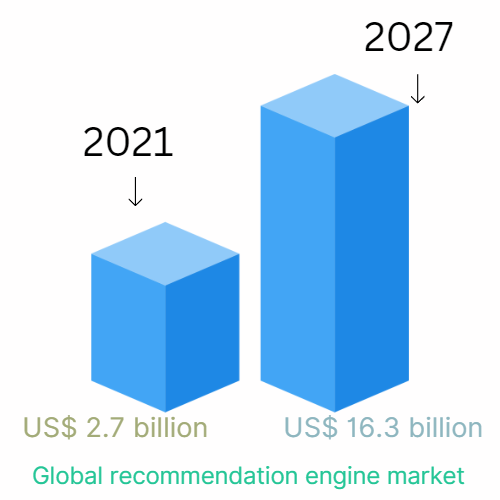

The figure shows an overview of the global market insight of businesses that uses recommendation systems.

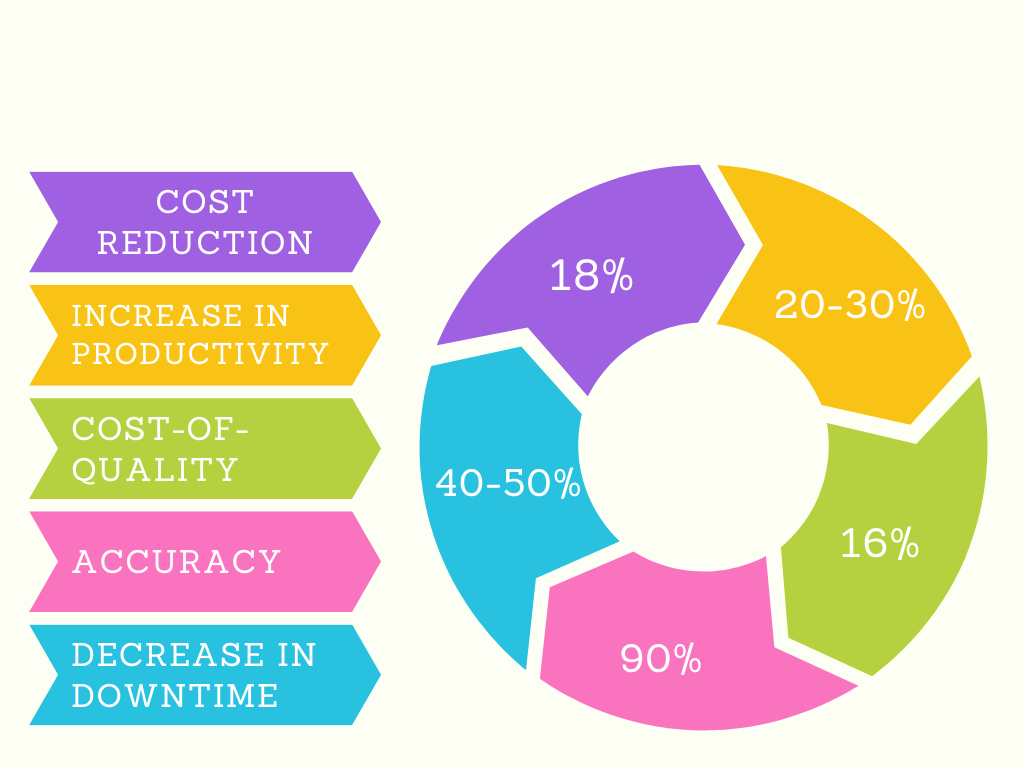

- Click-through rates-The click-through rate (CTR) helps to measure how many clicks are generated by the recommendations. The CTR is a critical metric in the recommendation. According to the study, personalized recommendations resulted in a 38% increase in clicks on average. Furthermore, recommender proved to be beneficial for longer user sessions, resulting in a 35% increase in CTR.

- Conversion rates– When compared to the previously used “naive” algorithm, the experimenters report an 89% increase in “add-to-wish list” actions after introducing a new similar-item recommendation algorithm on the page that users see after losing an auction. The study discovered that using alternative recommendation strategies can increase the conversion rate to an external marketplace by more than 90% on a different, much smaller marketplace for electronic gadgets. According to the survey, 93% of businesses see an increase in conversion rates as a result of recommendations.

- ROI– According to Mckinsey, Netflix’s revenue increased by 32.3%, while Amazon’s revenue increased by 21.11% in a year.

- Engagement– In various application domains, higher user engagement is considered to lead to increased levels of user retention, which often directly translates into business value. Several real-world studies of recommender systems have found that the presence of a recommender increases user activity.The study discovered that when recommendations were displayed on the page, visit lengths were 2.5 times longer. According to the market analysis , user activity and sessions have increased by 80%.

According to researchandmarket, the global recommendation engine market reached a value of US$ 2.7 billion in 2021. Looking forward, the market is projected to reach US$ 16.3 billion by 2027.

Are recommendation systems worth it?

Typically, online businesses do not share detailed information about how they profit from the use of recommendation systems and how frequently their end users follow the recommendations. According to the findings, recommendation engines provide greater business value and have a large potential for personalization and suggestion. As a result, recommender systems are one of the most prominent success stories of artificial intelligence and machine learning in practice, frequently resulting in significant benefits for businesses.

Makoro™ brings the power of recommendations to the manufacturing supply chain.

Makoro™ recommendations consistently improve asset and process performance – providing secure access to your plant predictions, insights, and recommendations from any device, anytime, anywhere. It is an important component of your remote operations strategy, allowing your operations personnel to make better, faster, timely, compliant and consistent decisions about plant operations remotely.

Moreover, the Recommendation Dashboard shows in real-time your operations gains from Makoro™’s recommendations and insights.

Schedule a call to learn how we can help you save. 15 minutes is all it takes.