The fundamental network structure of #5G, combined with #IIoT will deliver a slew of secure, fast, and reliable data-driven applications for the manufacturing and supply chain.

Lighthouses – case studies of future manufacturing workforce

These 10 Lighthouses recently (in July) joined the team of 16 Lighthouse factories around the world, a majority of them in China. These factories that have taken #fourthindustrialrevolution technology from pilots to integration at scale, realizing significant financial and operational benefits.

Manufacturing servitization using Makoro™

Servitization is not actually a dictionary word – it is a concept that has come about recently while innovating on business models for manufacturers to engage more proactively and meaningfully with their end customers. It has been defined as “a process of building revenue streams for manufacturers from services”.

Take control of your proprietary data

The current IoT landscape is highly OEM-centric – it is heavily OEM-data-biased and at first services the interests of the equipment manufacturer. The end customers, the asset operators, plant owners, and process owners, have been sharing their operational data with their OEM equipment suppliers in return for insights into asset conditions and improved maintenance. And depending on the strategies deployed by the OEM, the end customers and operators often have valid concerns about the credibility of these insights delivered by the OEMs. And more often than not, it is impossible to get a true understanding of the approaches that led to the insights. (Take the over-simplified example of auto-manufacturer-recommended oil change every 3,000 miles.)

However, the end customers are increasingly demanding improved equipment and process reliability across their whole asset/equipment estate. This estate includes operational assets from multiple OEM providers across the entire set of manufacturing and medical laboratory processes, across multiple geographies, with multiple technologies and wide variations in equipment age. And every organization needs a systematic and coordinated set of activities and practices which sustainably manages all its assets’ performance, risks and expenditures over their life cycles for the purpose of achieving the organizational strategic plan.

Given these conditions, reliance on OEM recommendations not only leads to fragmented asset management strategies across the estate, but these recommendations have mostly proven to be the least effective for assets with medium to high criticality.

End customers and asset operators require clear and accurate recommendations on process optimization. Unfortunately, many consider this information to be their proprietary data, their playbook, their operational cookbook, and this is confidential to their ecosystem. In addition, many manufacturing or process operations are competitive and thus deferential to their product offering and cost.

There is a trend in which end-customer business models move to a lower-cost model, with the lower deployed operational resource. However, employed process technology generally is increasing in complexity.

Makoro™, therefore, recommends and delivers continuous improvement in quality and asset/equipment total through-life cost while maintaining high process availability (OEE) and delivering a reduction in downtime based on the end customers proprietary data from their whole ecosystem while still sharing nominated data with selected OEM providers.

Makoro™ is a technology for the end-user, the asset operator.

Makoro™, by design, works with multiple and simultaneous data sources, protocols and connected and non-connected devices, legacy operational, and maintenance data. You do not have to have IoT fully deployed with every edge device reporting to get immediate value.

We sell directly to the asset operators, through process consultants and also to OEMs that recognize any IoT platform must support all the process stakeholders while protecting the intellectual proprietary of the end customer process.

We also licence our technology via API to extend the capability offering of already deployed Enterprise Asset Management (EAM), Field Service Management (FSM), Asset Performance Management (APM), Computerized Maintenance Management (CMMS) and Enterprise Resource Planning (ERP) systems.

Too many people tell you where the problem is, but shy away from recommending solutions. This is where Makoro™shines – we not only pinpoint the problem but also recommend solutions.

Makoro™ lets you take control of the proprietary data you collect from your line and your manufacturing process devices. You decide what you wish to share with the OEMs providing your equipment maintenance.

Sign up for a 10-Day Outcome Challenge to learn more about what Makoro™can do for your business.

Welcome Enterprise Infotech – our first strategic APAC partner

We are excited to announce the launch of our #newpartnership! CodeData joins hands with Enterprise Infotech based out of Melbourne, Australia, on a Strategic Partnership Alliance for Makoro™ distribution and implementation in APAC.

OI4 to drive Smart Manufacturing adoption

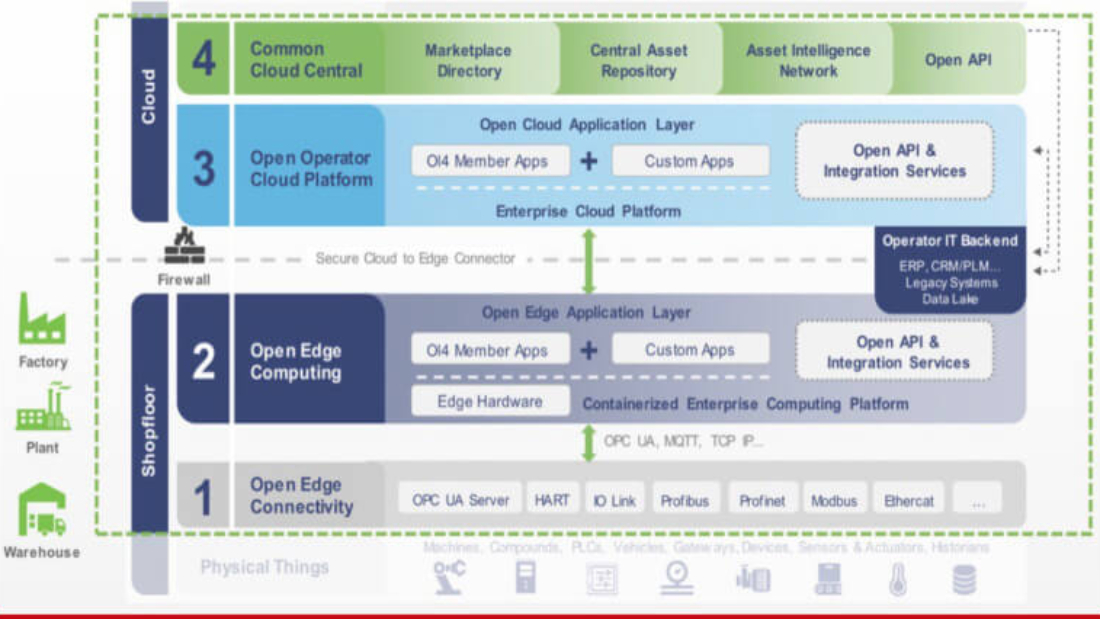

OI4 – The Open Industry 4.0 Alliance that was formed at#hannovermesse2019 plans to take the alliance global. The Open Manufacturers Cloud Platform could be a great forum to drive adoption

Makoro v0.8.1 Launched

From data to recommendations in minutes.

#MakoroAI #ContinuousIntelligence #RecommendationEconomy

Talk to us for a demo: https://calendly.com/sam-sur/m-intro

Predictive analytics: Transforming data into Recommendations

Predictive analytics technologies are being used to revolutionize manufacturing operations across all sectors. Not only manufacturers but these technologies are also being used by Asset Owners to derive values based on their data instead of relying on specific OEM’s to deliver “proprietary” value. Throughout the pandemic, these technologies have also been assisting Asset Operators in managing the lifecycle of critical assets distributed across several geographic locations.

Historically, assets of various types – from those on factory floors to those in the field – have exclusively relied on calendar-based management. This meant that decisions were taken, work orders were scheduled, and pieces were ordered simply because a calendar said it was time, rather than because they were actively managed to provide value.

Reactive asset management is costing businesses millions of dollars. The magnitude of the actual impact is even unknown to most asset owners and operators.

The other issue is the siloed focus on maximizing the throughput of an asset, rather than a focus on building end-to-end intelligent operations that cut across different OEMs.

Predictive and prescriptive analytics technologies leverage artificial intelligence (AI) and advanced analytics to develop intelligent operations. These technologies allow manufacturers, owners and operators to predict the operational impact to an asset, the line, the floor or to a location. Here is how Makoro™ leverages predictive and prescriptive technologies in building intelligent operations.

Makoro™ Edges connect with assets and devices on the front end and communicate with Makoro™ Hub on the back end. It transmits machine and process data such as flow rate, oil and water temperatures, vibration measurements, and machine operating hours.

After that, this data is combined with data from different operations and business sources. This is accomplished through Makoro™ Bind, the connector’s interface. After that, it is analysed using a combination of market rules and Makoro™ Mind’s predictive, Al-powered algorithms. While Makoro™ predicts a possible issue, it also does a root cause analysis of the issue. Further, it proactively generates maintenance requests, schedules and assigns the requests, and makes duration, fix and parts recommendations. As data flows through the Hub, Makoro™’s continuous intelligence delivers “unexpected” predictions, insights and recommendations.

Makoro™ learns and evolves as customers engage with the recommendations. And gradually establishing a “golden” operations workflow in which asset management actions are data-driven, traceable, and have been validated by the customer’s workforce.

Through deep-domain artificial intelligence, Makoro™ delivers a rapid time-to-value for customers. It results in higher asset uptime, lower cost of operations, lower maintenance costs and higher workforce adoption.

The ability to anticipate is the competitive advantage in the fast-paced #Industry40 adoption and Makoro™’s #PredictiveRecommendations give you that edge.

MakoroTM’s dynamic learning framework brings operations management to the next level, allowing sets of validated guidelines with extremely high validity and trust scores to be repeated across several locations to maximise value. So instead of sharing data as reports and dashboards, they share recommendations/prescriptions.

Makoro™’s Recommendations Dashboard tracks asset performance metrics and correlates them to recommendations. Leaders who have embraced Makoro™ have achieved more than 11% improvement in their operations agility.

To get started with Makoro™, sign up for our 10-Day Outcome Challenge.